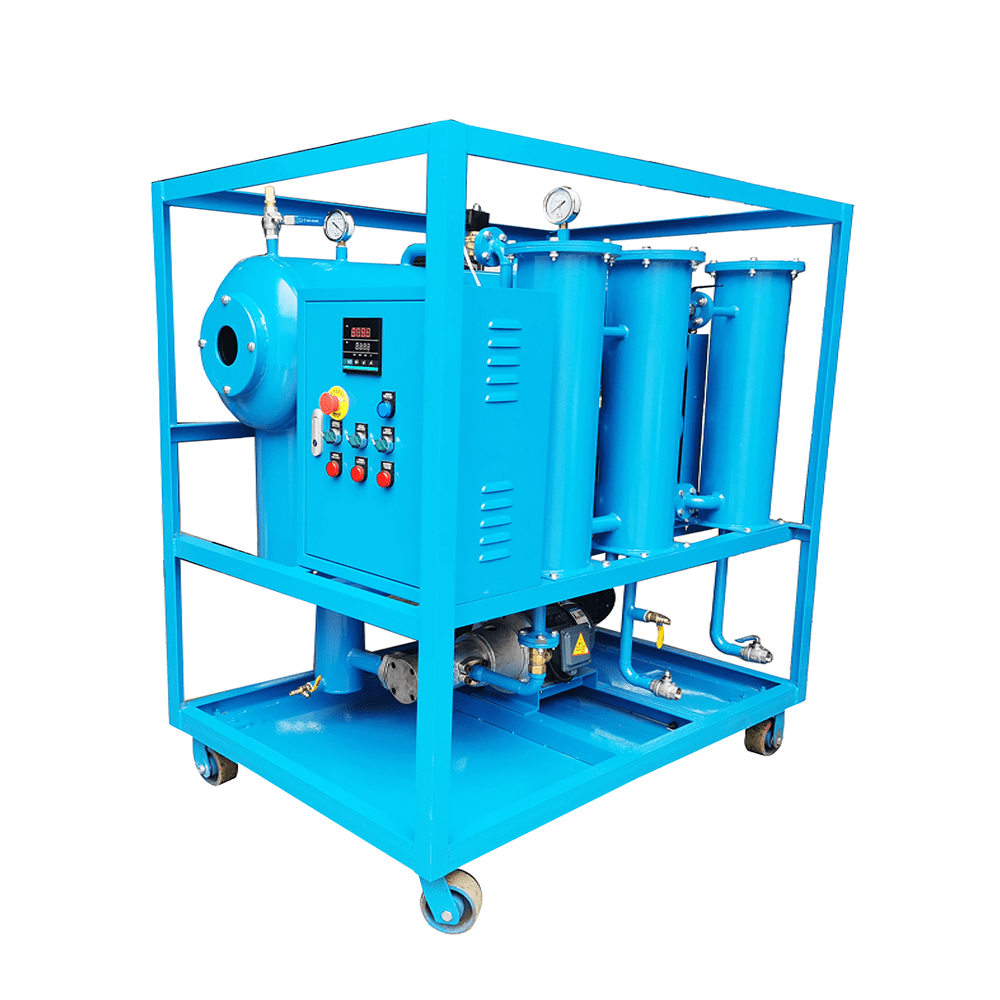

High Efficiency Vacuum Pump Oil Filter

- Wrindu

- Shanghai, China

- about 25 days

- 5000 set/month

The ZYD-F Series High Efficiency Vacuum Pump Oil Filter offers complete filtration, dehydration, degassing, and particle removal for insulating oils, enhancing oil quality and extending transformer oil lifetimes in an environmentally friendly and cost-effective manner.

Description

The ZYD-F series of High Efficiency Vacuum Pump Oil Filter is engineered for comprehensive filtration, dehydration, degassing, and particle removal of insulating oils used in transformers. This system not only offers standard oil purification services like degassing, drying, and particulate removal but also reduces acidity, sludge, and other soluble oil decay products, enhancing the oil's dielectric strength value (BDV). The result is an improvement in the physical and chemical properties, making the treated oil comparable to new transformer oil.

The ZYD-F series High Efficiency Vacuum Pump Oil Filter boasts advantages such as high working vacuum, rapid oil filtration speed, and low maintenance requirements. These systems provide an extremely cost-effective and environmentally friendly method for extending the lifespan of transformer oil beyond 20 years.

Furthermore, the ZYD-F series High Efficiency Vacuum Pump Oil Filter is well-suited for the treatment of new oils and the reconditioning of used transformer oils in EHV class transformers, shunt reactors, and other oil-filled equipment in power plants, power stations, electric power companies, and power transmission equipment. It is particularly suitable for on-site installation, maintenance, and purification of high-grade new oils or running oils from large power transmission and distribution equipment and transformers on the national main power grid, which is above 110-750KV. This system can shorten the oil treatment period for transformer installation and maintenance, ensuring that the treated oil meets the specified limits at the rated capacity.

Features

1. Transformer Oil Purifier Machine utilizes a double-stage high vacuum pumping system with superior evacuating capabilities, achieving an ultimate vacuum value of ≤10Pa.

2. Features unique "T" shape double vacuum separation technology, double-stage thin film drying degassing technology, and doubled evaporation area and degassing time.

3. Patented degassing tank with anti-foam structure and dual electronic foam monitoring system (key components from Switzerland) to completely prevent oil from entering the vacuum pump.

4. Reliable control system with optimized design of control interlock protection devices, overpressure alarms and protection, phase sequence protection, ensuring stable operation of the entire machine over an extended period. Advanced technologies such as an automatic pressure alarm system, automatic overload protection system, automatic constant temperature system, automatic foam elimination system, and automatic oil blowout prevention protection system ensure safe and stable unattended operation.

5. Transformer Oil Purifier Machine atomized oil particles are less than 50μm in size, significantly increasing the efficiency of water and gas molecules escaping from oil molecules.

6. High-density electrical heaters with a surface efficiency of less than 1.5 W/cm2 and indirect heating prevent local overheating, oil cracking, and aging.

7. Heater system installed with liquid level and temperature protectors to prevent instantaneous high temperatures and blank heating without oil.

8. Prepositioned vacuum pump cooler to reduce water or vapor from entering the vacuum pump, decreasing the frequency of changing vacuum pump oil and extending the vacuum pump's lifetime.

9. High-precision filter elements with a filter rating of up to 1 micron prevent particles from re-entering the transformer.

10. Automatic oil discharge pressure protector to continuously monitor the pressure of oil filters, effectively protecting the machine and operators.

11. Transformer Oil Purifier Machine adopts a high-pressure screw type oil pump for stable oil delivery, low noise, and long life.

12. Automatic float ball valve and electronic oil level automatic control system for automatic foam elimination, automatic oil level control, and unattended operation.

13. Applicable for vacuum oiling and drying of power transmission equipment.

14. The machine is fully enclosed for weatherproof, sandproof, windproof operation, suitable for outdoor usage.

Parameters

Items | Unite | ZYD-30F | ZYD-50F | ZYD-100F | ZYD-150F | ZYD-200F | ZYD-250F | ZYD-300F | |

Flow rate | L/min | 30 | 50 | 100 | 150 | 200 | 250 | 300 | |

Working vacuum degree | MPa | -0.08 ~ -0.099 | |||||||

Working discharge pressure | MPa | ≤ 0.4 | |||||||

Ultimate vacuum value | Pa | ≤10 | |||||||

Temperature control range | ℃ | 20 ~ 80 | |||||||

Power supply |

| 415V/50Hz, 3 phases, 4 wires (or as per your requirements) | |||||||

Fault-free working hours | h | ≥4000 | |||||||

Continuous working hours | h | ≥150 | |||||||

Noise | dB(A) | 65 ~ 85(Determined by device configuration) | |||||||

Heating power | kW | 30 | 60 | 90 | 120 | 135 | 150 | 180 | |

Total power | kW | 33 | 66 | 102 | 135 | 152 | 168 | 208 | |

Inlet (outlet) diameter | mm | Φ25 | Φ32 | Φ42 | Φ50 | Φ50 | Φ60 | Φ60 | |

Indicators after filtration | Breakdown voltage | kV | 65 ~ 80 | ||||||

Moisture content | ppm | ≤5 | |||||||

Gas content | % | ≤0.1 (Vol) | |||||||

Filtration precision | μm | ≤1 | |||||||