Learn How To Detect Battery Status In Substations In One Move

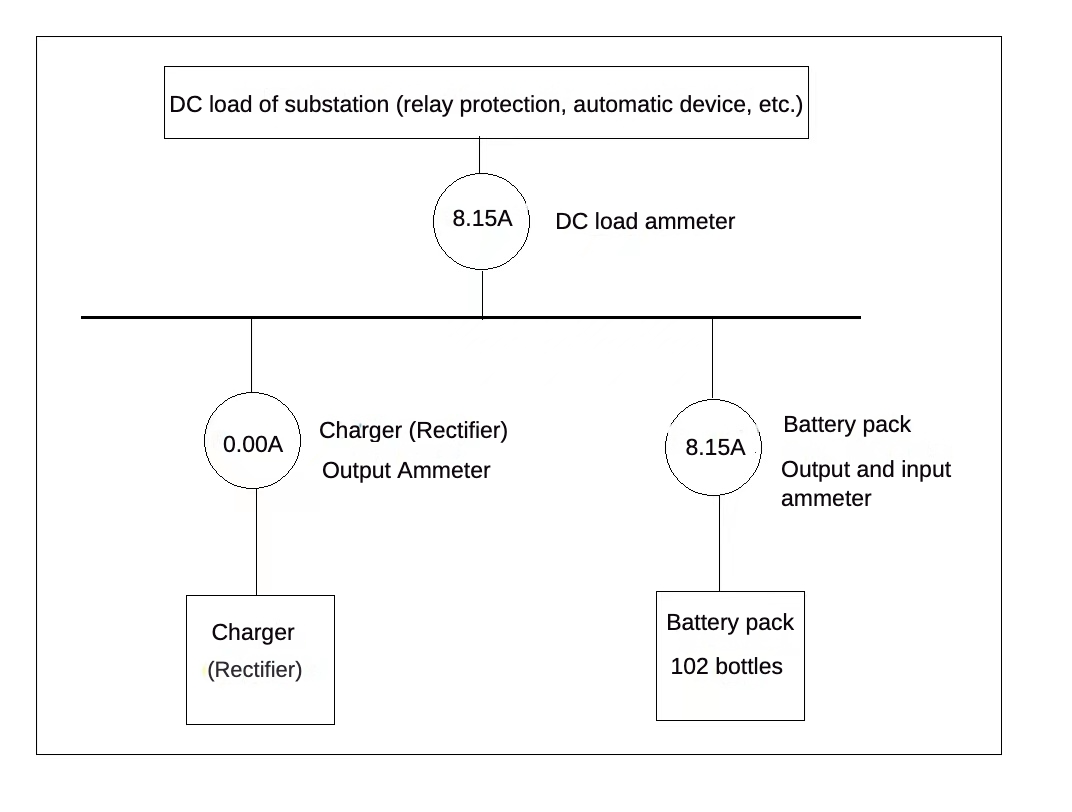

When the battery is running normally, the charger and the battery pack run in parallel, the charging voltage is set to 230 volts, the battery pack is fully charged, the ammeter shows 0 A, the charger has a DC load, and the load current shows 8.15 A. At this time, the system is powered by the charger, and the battery open circuit fault is not easy to find.

When the station power fails or the front-end input AC power of the charger trips, the battery pack carries the DC load. Once the DC loop (battery pack) is open or the internal resistance exceeds the limit, the DC system in the station will be paralyzed. At this time, the power transmission and distribution If the line fails, the protection cannot operate correctly, which can easily lead to major accidents such as over-level tripping.

▼Analysis of causes of battery defects

Substation operation and maintenance personnel are the "physical examination doctors" of the battery, and the quality of their inspections directly affects the healthy operation of the battery. By analyzing many substation DC system accident cases, it is found that the main reasons for battery defects are the following three points:

First, there are loopholes in the supervision and inspection of the maintenance plan, the operation and maintenance personnel did not do a good job in battery maintenance, and the internal resistance test and nuclear capacity test seriously exceeded the maintenance cycle.

Second, the implementation requirements for key countermeasures have not been implemented, and operation and maintenance personnel have not paid enough attention to battery open circuit inspections, and are not clear about the serious impact of battery defects on the power system.

Third, the team training plan was not implemented in a closed loop. The operation and maintenance personnel did not know how to carry out the battery open circuit inspection, and the battery open circuit inspection method was incorrect or was not carried out.

▼How to check battery status

When the DC system of the substation is operating normally and the battery pack is not isolated, operation and maintenance personnel can check the status of the battery through an open circuit test to quickly discover battery defects. The specific inspection methods are as follows:

When performing battery open circuit detection, set the charging voltage of the charger (rectifier) to 220 volts, the output current of the charger (rectifier) will be displayed as 0 amps, the battery pack is in a discharge state, the ammeter displays 8.15 amps, and the battery pack is discharging with DC Load, the load current shows 8.15A. During the discharge process, the battery voltage and DC bus voltage will drop from 230 volts to 220 volts. Operation and maintenance personnel can judge the working status of the battery by observing the entire discharge process. The specific judgment method is as follows:

1

Normal working status of battery

If the discharge time exceeds 10-15 minutes and the charger (rectifier) current shows 0 amps, it means the battery pack is operating normally. After the judgment is completed, the output voltage of the charger (rectifier) needs to be adjusted to 230 volts immediately, and the battery will automatically switch to float charge state after equalizing charge to ensure that the battery is in a ready state.

2

Battery open circuit operating status

If the output current of the battery pack always displays 0 A in this mode and the output current of the charger is 8.15 A, it means that the battery pack is in an open circuit state. Report it to a professional immediately and report a critical defect for processing.

3

Battery is running in bad condition

If the discharge time is less than 5 minutes, the output current of the battery pack gradually drops to 0 amps, and the output current of the charger gradually rises to 8.15 amps, it means that the battery pack has problems such as excessive internal resistance, insufficient capacity, or loose wiring. Please charge immediately. Adjust the output voltage of the machine (rectifier) to 230 volts, conduct infrared temperature measurement of the battery pack, report to professionals, and report serious defects for processing.

Operation and maintenance personnel must have a work mentality to prevent problems before they occur, regard the battery as the core equipment of the substation DC system, and regularly carry out maintenance projects (such as open circuit inspection, internal resistance test, nuclear capacity inspection, etc.) to ensure that the battery is always in a state of readiness.

END