How to test a circuit breaker?

What makes circuit breaker testing important?

Circuit breaker testing improves overall electrical safety by confirming that each breaker works as expected during faults. Regular testing reduces the risk of failure and lowers the chance of unexpected shutdowns. The process also protects valuable equipment from damage and helps facilities avoid costly downtime. With consistent testing, the entire electrical system operates with higher reliability and stronger long-term performance.

Circuit breaker testing procedure

The procedure checks electrical and mechanical health. And the steps guide technicians through each test.

Step-by-step process

| Step | Task | Purpose |

|---|---|---|

| 1 | Visual inspection | Find wear, damage, or dirt |

| 2 | Insulation Resistance test | Confirm strong insulation |

| 3 | Contact Resistance test | Confirm strong conductivity |

| 4 | Timing test | Check opening and closing speed |

| 5 | Dielectric test | Check insulation strength at high voltage |

| 6 | Trip tests | Verify correct trip functions |

| 7 | Documentation | Support future analysis |

Typical timing expectations

| Action | Typical Time |

|---|---|

| Trip time | 20–45 ms |

| Close time | Under 60 ms |

| Phase difference | Under 2 ms |

What tools support accurate testing?

| Tool | Function |

|---|---|

| Megohmmeter | Runs IR tests |

| DLRO | Measures contact resistance |

| Circuit Breaker Analyzer | Records timing and motion |

| Hi-Pot tester | Runs dielectric tests |

| Primary Injection Set | Checks trip functions |

| Clamp meter | Checks current |

| Thermal camera | Detects hot spots |

How do technicians stay safe during testing?

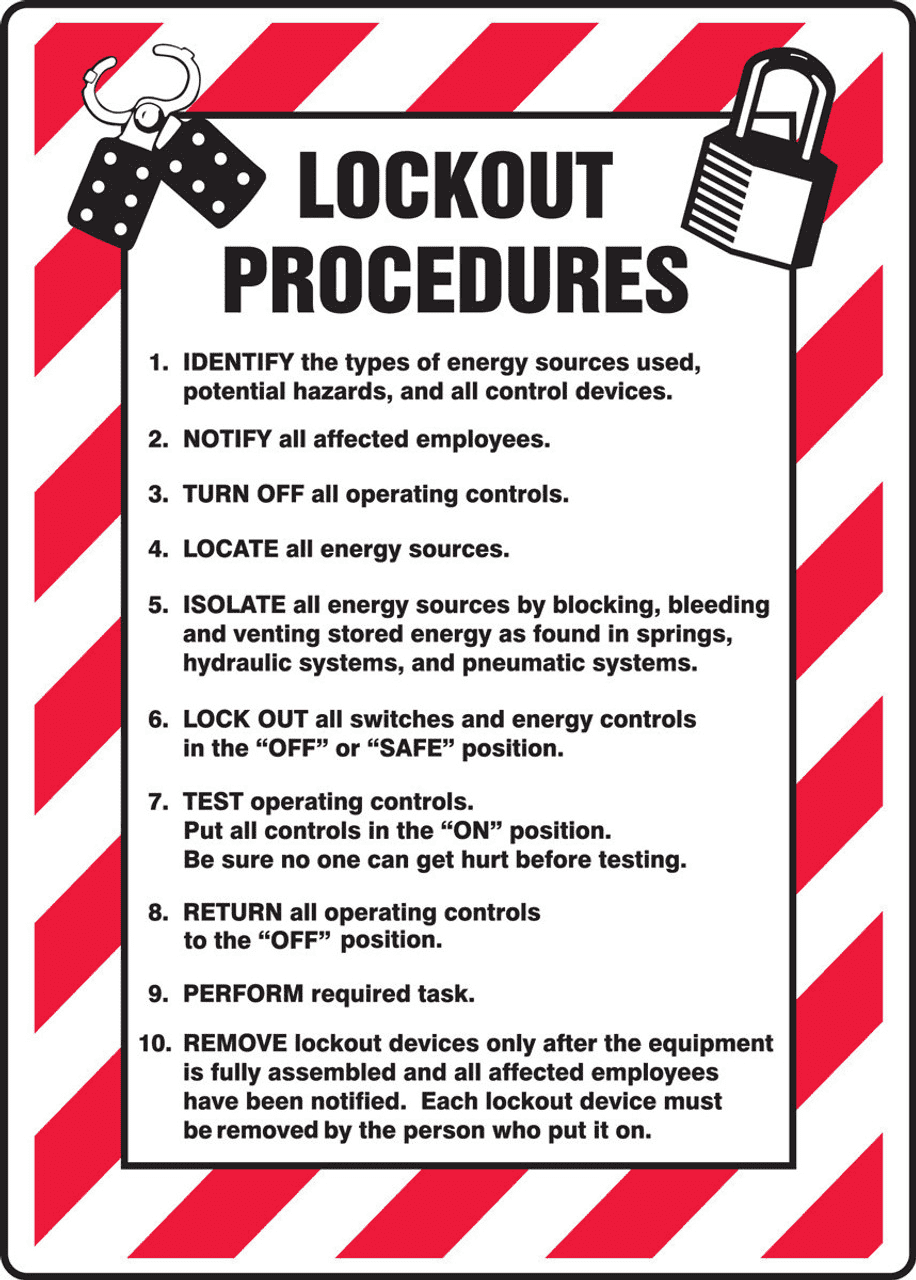

Technicians follow NFPA 70E rules. They cut power before work whenever possible. And They use Lockout/Tagout to secure equipment. Besides, they use Energized Electrical Work Permits when necessary.

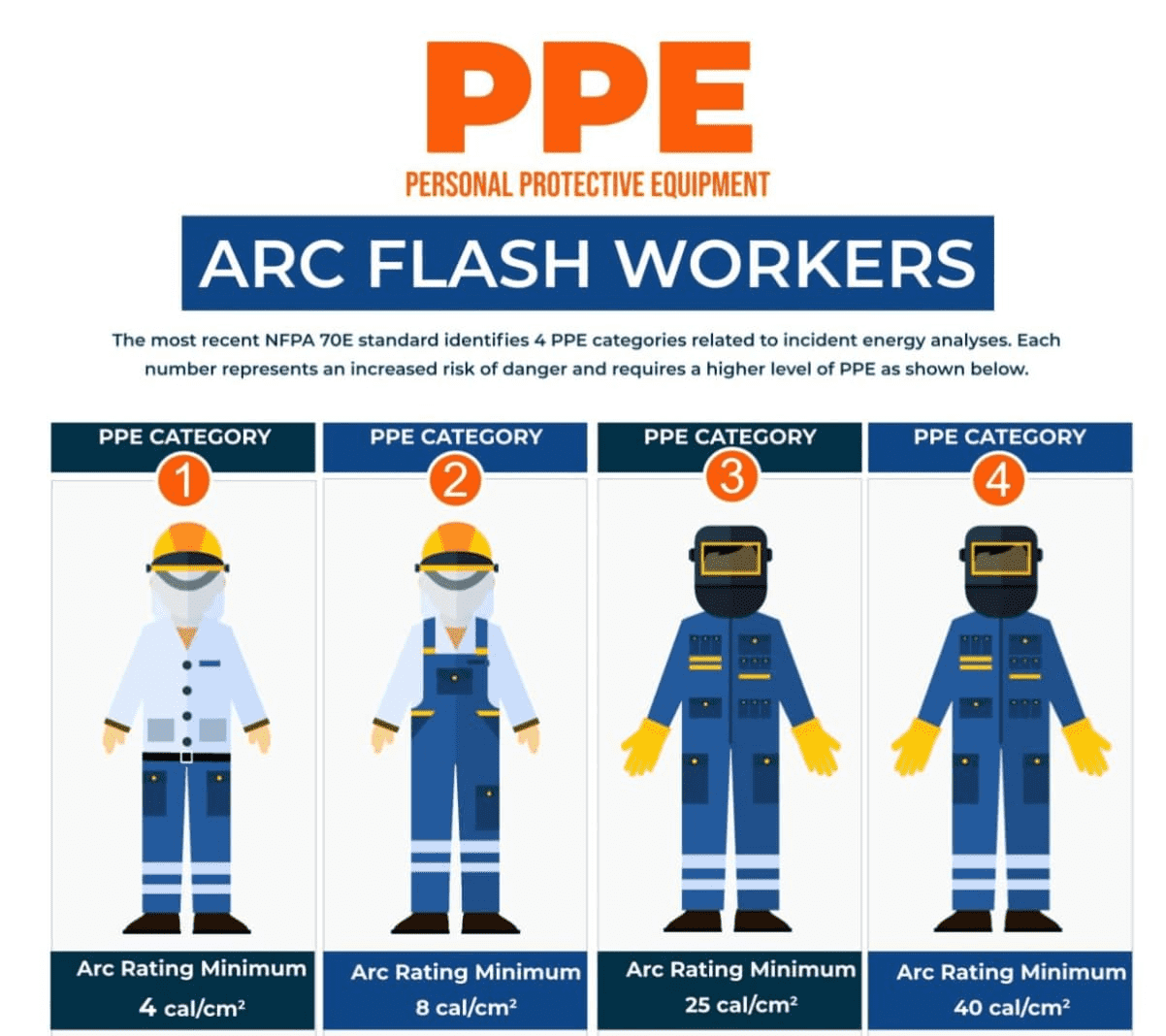

Qualified workers wear correct PPE for each job.

When should technicians test circuit breakers?

Testing supports each phase of the breaker's life.

| Stage | Purpose |

|---|---|

| Development | Confirm design quality |

| Production | Confirm manufacturing quality |

| Commissioning | Approve field installation |

| Maintenance | Locate issues early |

| Re-commissioning | Approve work after service |

Testing frequency changes with voltage and environment.

| Voltage Type | Frequency |

|---|---|

| Low Voltage | Every 1–3 years |

| Trip Tests | Every 3–5 years |

| Medium Voltage | Yearly or semi-yearly |

| High Voltage | Yearly or semi-yearly |

What problems do technicians often find?

Technicians meet both mechanical and electrical issues.

Common mechanical issues

Dirt blocks movement

Worn parts slow motion

Dry joints increase friction

Misalignment changes stroke length

Common electrical issues

Loose wiring

Weak insulation

High contact resistance

Incorrect trip settings

Which industry standards guide circuit breaker testing?

Several major standards define how technicians should test circuit breakers.

The primary ones include IEEE C37.09, which outlines test procedures for AC high-voltage breakers, and IEC 62271-100, which covers requirements for AC circuit breakers in high-voltage switchgear. NETA also supports the industry with NETA ATS for acceptance testing and NETA MTS for maintenance testing. These documents offer broad guidance for many types of electrical equipment, including circuit breakers.

Wrindu's Circuit Breaker Testing Solutions

With Wrindu's testing solutions, you can check circuit breakers safely and easily. Our tools support many test types, such as insulation checks, low-resistance measurements, and trip and close time analysis, so you can confirm proper breaker operation.

When you use our proven equipment with a solid testing procedure, you can evaluate breaker performance, spot developing issues, and avoid expensive outages. Wrindu delivers strong accuracy and fast results, helping you test more efficiently and maintain a safe, reliable electrical system.

Click to ask for technical help from our experts.

Delivery of circuit breaker testers to Indonesia.

Do you know these applications of the primary current injector tester?

Differences between megger test, Tan delta test and Hi-pot Test.