Can Tan Delta Help Predict Failures Before They Happen?

Questions about Tan Delta

What are the key meanings of dielectric loss factor?

What is meant by loss angle?

What are the main factors of dielectric loss factor?

How is tan delta related to Q?

How to predict failures by tan delta value?

What are the key meanings of dielectric loss factor?

Tan delta, also known as Loss Angle or dissipation factor, is a parameter that measures the energy loss of a dielectric under the action of an AC electric field. It represents the ratio of energy loss due to polarization and conductivity to stored energy in the medium, and is usually expressed by the dielectric loss tangent (tanδ). The following are some key meanings of dielectric loss factor:

-

Energy Loss: The dielectric loss factor reflects the degree to which the dielectric dissipates energy in the form of heat energy under an AC electric field.

-

Material purity: It can reflect the purity of the material. The higher the purity is, the lower the dielectric loss factor of the material is. Impurities and defects increase energy loss.

-

Temperature stability: The change in dielectric loss factor with temperature can reflect the temperature stability of the material. For temperature-stable dielectric materials, their loss factor changes a little bit at different temperatures.

-

Aging Effect: The dielectric loss factor can reflect the aging effect of the material. Over time, the material may increase its loss factor due to aging.

-

Design Considerations: Dielectric loss factor is an important parameter when designing capacitors and other electronic components. Materials with low dissipation factors can reduce energy loss and improve component efficiency and thermal stability.

-

Quality Control: The measurement of dielectric loss factor can be used as a way used for quality control to help detect and guarantee the performance of dielectric materials to meet specific standards and requirements.

What is meant by loss angle?

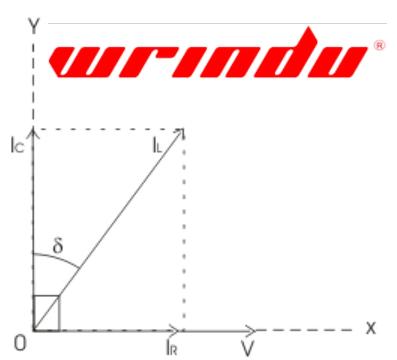

Loss Angle equals to Tan Delta. According to Oxford, the angle by which the angle of lead of the current is less than 90° when a capacitor or dielectric is subjected to sinusoidal alternating electric stress. It is mainly used to measures the energy loss of a dielectric.

If the loss angle is too large, that is, δ is too large. It means tan delta value is too large, which indicate the power equipment has serious losses. And to remember, if tan delta value increases, it shows energy losses, which also indicates the insulation is deteriorating, often due to aging or moisture.

What are the main factors of dielectric loss factor?

Factors that affect dielectric loss factor include dielectric type, thickness, temperature, humidity, and electromagnetic wave frequency. These factors work together to cause the dielectric to lose energy under the influence of an electric field. The magnitude of this loss is characterized by the dielectric loss factor.

| Factor | Impact Mechanism |

| Material Type | Different materials have varying molecular structures and polarities. Polar materials exhibit greater energy loss in an electric field due to enhanced molecular movement. |

| Thickness | As thickness increases, electric field intensity may decrease, but the overall energy loss can increase due to the larger volume of the electric field acting on it. |

| Temperature | Higher temperatures increase molecular movement, leading to higher energy loss. This effect is more pronounced in temperature-sensitive materials. |

| Humidity | Increased humidity raises the water content, enhancing polarity and energy loss; it significantly lowers the insulation performance in insulating materials. |

| Electromagnetic Frequency | At higher frequencies, the molecular polarization cannot keep up with the changes in the electric field, causing an increase in the dielectric loss factor. |

How is tan delta related to Q?

The Dissipation Factor (DF) and Quality Factor (Q) are two crucial parameters that describe the performance of dielectric materials in an alternating electric field, and they are directly related to each other.

The Dissipation Factor (DF) is the ratio of energy lost as heat to the energy stored in a dielectric material under the influence of an alternating electric field. It is often represented by the tangent of the loss angle (tan δ).

The Quality Factor (Q) refers to the ratio of the energy stored in an inductor or capacitor in an AC circuit to the energy dissipated during one cycle. It is a dimensionless quantity that indicates the performance of resonant components or circuits.

The Q value is the reciprocal of the Dissipation Factor (DF), meaning Q = 1/DF.

This formula implies that a lower DF leads to a higher Q value. It reflects reduced energy loss and better performance of the material.

In the design of electronic components like capacitors, a high Q value implies low dielectric loss, which enhances component performance, reduces energy loss, and improves efficiency. And In resonant circuits, a high Q value results in a narrower bandwidth and higher selectivity, which helps improve signal quality.

DF is influenced by factors such as the molecular structure of the material, molecular motion, temperature, and frequency. The required Q value depends on the specific application, as different applications have varying demands for Q.

How to predict failures by tan delta value?

A high tanδ value generally means an increased ability of the material to dissipate energy (also known as damping) and greater energy losses during transformer testing equipments. In terms of insulation, higher values of dielectric loss tangent indicate degraded or contaminated insulation, leading to higher energy losses and potentially shortened service life of equipment.

A dissipation factor tester is a device used to measure the dielectric loss of insulating materials. It evaluates material properties by measuring the dielectric loss tangent (tgδ) and capacitance, thereby determining the energy loss under an electric field. These testers typically use bridge or direct (vector) measurement methods and can be used to test the capacitance and dissipation factor of high-voltage electrical equipment.

The RD6000A Transformer Tan Delta Tester from WRINDU breaks through the traditional bridge measurement method for the tan delta test of transformer. It adopts frequency conversion power supply technology and uses single-chip microcomputers and modern electronic technology for automatic frequency conversion, analog-to-digital conversion, and data operation. RD6000A can do interference resistance, a quick tan delta testing, high measurement accuracy, fully digital automation, and straightforward operation.

The tester employs a high-capacity switching power supply that generates clean 45Hz and 55Hz sine wave outputs. It applys automatic voltage regulation with outputs reaching 10kV, perfectly suitable for precise transformer tan delta testing. The built-in 50Hz noise suppression guarantees stable operation in high-interference environments.

If you are still have questions about tan delta, you can click the following links:

What is the tan delta test on a transformer?

You may not know about tan delta test.

Click here to find iec standards about tan delta tester.